OEM – CUSTOMIZATION

We can design motherboards and models according to customer requirements. After the client puts forward the design requirements, Our R&D team will evaluate the feasibility of the plan and the design cycle according to the design requirements. In pursuit of perfection, our R&D will provide some Suggestions for improvement to the customer's design requirements with professional knowledge and valuable experience, and collect feedback from customers. To produce the product can meet customer needs and market needs.

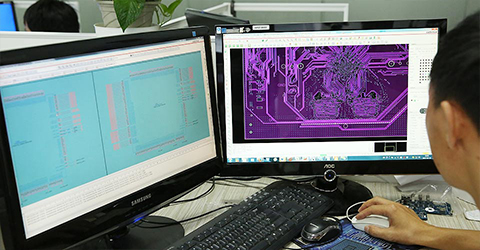

OEM-Motherboard R&D

Motherboard R & D is based on the customer's requirements (CPU, ddr, flash, wifi, BT, Ethernet, usb3.0/2.0, type-c, sd card, coaxial fiber and other functions), designed to meet the requirements of the Schematic (SCH), then make a BOM list based on the schematic diagram, procurement according to the BOM list to complete the cost quotation and procurement of materials; schematic diagram is completed, the PCB into the schematic network and structure DXF file PCB design, After the PCB design is completed, output Gerber file PCB factory production PCB board. The Models research and development are based on the customer's appearance ID requirements and PCB interface location, interface package, installation method, cooling methods, etc., design 3D mold graphics, 3D model design after the completion of the output Stp file and structure DXF file Stp file for the production of CNC Hand board, structured DXF file for PCB design. After the PCBA sample is completed and the CNC sample assembly verification is completed, new model is done. DoMarket research first, according to market model (mainly inspect model, configuration, function, new experience) and product planning, confirm the corresponding function and configuration and estimate the cost. After the assessment is passed, design the schematic SCH according to the function and Configuration, and then Completion of BOM-production and PCB design, BOM cost calculation and completion of sample material procurement after completion of the design, at the same time the schematic design, 3D mold design at the same time, after the completion of the 3D Model design output Stp file and structure DXF file, Stp file For the production of CNC Shouban, the structure DXF file for PCB design. After the PCBA sample verification test is completed and the CNC sample assembly verification is completed, the model is done.

Reliable Manufacturing & Laboratory Test Capabilities

|

|

|

|

SMT Production Line GKG-G5 Printing Machine |

SMT Production Line Panasonic NM-EJM6D Printing Machine |

SMT Production Line Mairay MR-1200A-II Reflow Welder |

|

|

|

PCBA 4 AOI Tester |

X-ray ST100 X Scenograph |

Test Equipment |

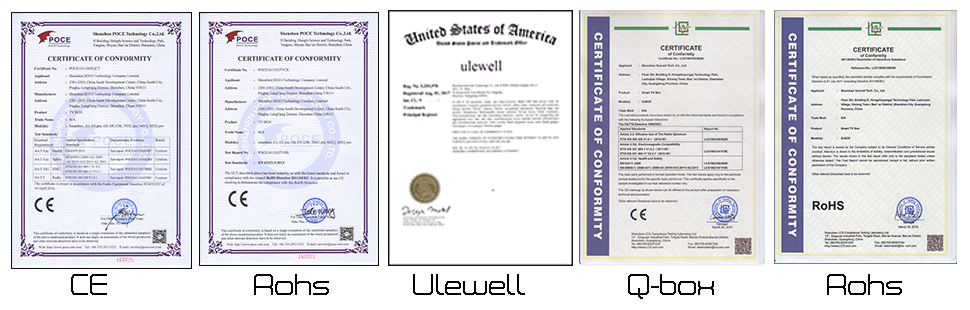

Certificates

Production management strictly implements 6s standard, ISO9001 quality system and TUV certification approved, and products are certified by CE/FCC/NCT/RoHS/TC.